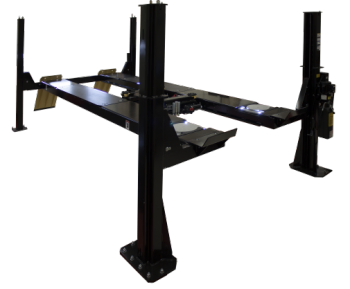

Capacity 12000 lbs

Lifting times 66 s

Drive-through width 103 inch

Power supply 230 VAC 1Ph 50/60 Hz

Distance between columns 115 inch

Minimum ceiling height 167 inch

Overall Width 139.75 inch

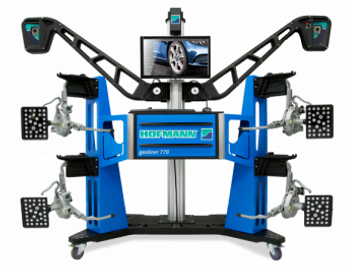

Hofmann 12k 2 Post

The 12k Two-Post lift features include; symmetrical lifting, long reaching front and rear arms, adjustable insert screw lifting pads, padded over-head shut off bar and enhancing optional accessories.

Part Number:

EELR738A

Heavy-duty, two stage arms enable heavy-duty, symmetric lifting up to 12,000 lbs

High quality rubber door guards provide added security against door damage

Single point, mechanical lock release allow the technician to disengage both columns simultaneously

Insert adjustable screw lifting pads with rubber contact surface for quick and easy vehicle set up

Premium powder coat finish provides a long lasting, durable finish

The padded overhead shut off system prevents vehicle damage from being raised too high

13′ 10″ or 14′ 7″ adjustable column height accommodates higher profile vehicles and provides maximum headroom to work underneath vehicles

ANSI/ALI ALCTV:2011 – Independently tested and validated, ALI certified to the current automotive lift standard