Wheel Size (AC200) 19″ – 39″

Tire Size (AC400) 19″ – 39″

Power supply115 VAC 1Ph 50/60 Hz

Track width 48″ – 96″

Wheel base 79″ – 180″

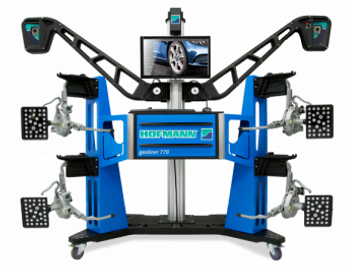

Hofmann Geoliner 770

Ideal for high-volume shops that specialize in alignments and wheel service, the Hofmann® geoliner® 770 Mobile Imaging Wheel Aligner delivers sophistication in a compact footprint, designed to fit where you need it and move pretty much anywhere else.The short boot-up gets your team to every job quickly, with faster measurements for more efficient, more accurate alignments every time.

Part Numbers

With AC 400 Clamps & Vin Reader – EEWA752BV3

With AC 200 Clamps & Vin Reader – EEWA752HV3

Groundbreaking User Interface –

The geoliner® 770 Mobile Imaging Wheel Aligner features a next-generation interface that provides instant access to critical tasks in an intelligent flow, ensuring vehicle-specific assistance is never more than just one click away.

Optimized Vehicle Selection Process

– Quick access to history right on the home screen

– Clear and comprehensive make/year/model selection

– Quick model search

– Manual and scanner VIN select, with live lookup feature

Quick-Select Language Support for Procedures and Printouts

– provide rapid changes between commonly used languages

All-New Graphic Displays

– with all screens optimized for maximum visibility and clarity

Video Speed Cameras Constantly Monitor Alignments, Providing Information at Every Step

– The geoliner® 770 Mobile Imaging Wheel Aligner’s advanced XD cameras and sophisticated monitoring algorithms find errors as they’re made, detecting problems with suspension stress and damage, rack, clamps, environment, and more – notifying users only when necessary, to save time and ensure accuracy on every alignment.

Compensate: Error is completely compensated with no notification to the user

Warn: Error is completely compensated with user warned that a correction action is required

Alert: Critical error leading to a bad alignment is detected; user notified that corrective action is required

Automatic Height Tracking Save Time on Every Job

– The geoliner® 770 Mobile Imaging Wheel Aligner automatic height tracking provides optimum placement of its advanced XD targets and cameras for more speed and more accuracy on every alignment. And since the lightweight, three-camera system folds to a compact size with a low center of gravity, the geoliner® 770 takes up less floor space in the shop and can be moved around easily whenever required.

With the AC400 wheel clamps, it virtually eliminates any worry of damaging rims by attaching with a single fast-action adjustment knob and only makes contact with the tire.

Additional Features

Next generation UI optimized for the high-volume user

Diagnostic alignment with “Compensate Warn Alert” intervention gets it right the first time

Unique camera beam design to fit through a standard doorway and protects cameras

Highly accurate and reliable XD camera technology