Wheel Diameter 12″-30″ (25-76 cm)

Maximum Wheel Width 17″ (43 cm)

Maximum Tire Diameter 47″ (119 cm)

Maximum Sidewall Height 8.4″ (21.336 cm)

Dimensions (D x W x H) 51″ x 73″ x 89″

Shipping Weight 2,050 lbs (930 kg)

Compressed Air Supply 110-170 PSI

Power Requirements 230V 1Ph 60Hz

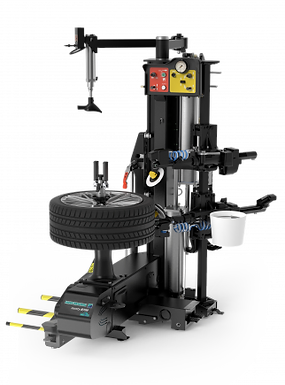

Hofmann Monty FA 1000

The Hofmann® monty® FA 1000 fully-automatic tire changer is designed to safely and efficiently change all types of tire and wheel combinations. The innovative design features on the monty FA 1000 include: computerized mount/demount programs, automatic tire diameter measurement, automatic laser-profiling of the wheel, integrated wheel lift, electro-hydraulic center clamping, two-speed drive system and top-side bead inflation.

Part Number:

EEWH734B

Do No Harm™ precise tool control avoids damage to expensive alloy wheels, protecting your revenue and ensuring customer satisfaction

Integrated bead pusher assists in the mount/demount process of the upper bead

Center post wheel clamping provides easy and precise wheel mounting and prevents rim edge contact with the mount/demount tool

Upper and lower integrated, servo driven bead breakers are automatically positioned

Smart Vision™ wheel and tire laser profiling – automatic laser measurement of the wheel edge assures precise tool positioning to speed tire removal and installation, reducing the opportunity for damage

Intelligent wheel lift reduces the risk of wheel damage and technician fatigue, reducing the risk of injury